Our Processes

Black Oxide

Black Oxide is a conversion coating for ferrous materials. Black oxide is a great choice for minimal build-up, the ability to add mild corrosion resistance, and for its appearance.

We use a hot bath of primarily sodium hydroxide (caustic soda) to convert the surface of the metal into magnetite (FeO4). The caustic soda bonds chemically to the surface of the metal, creating a porous base layer on the part. To achieve maximum corrosion resistance, black oxide must be covered with a topcoat. We offer several different options including wax, hot oil, lacquer or clear amine sealers. Once sealed with the topcoat, black oxide offers a lustrous finish.

We offer black oxide in both rack and barrel. Our black oxide process is REACH, ROHS, ELV and WEEE compliant.

Chromates

Chromate conversion coatings are used for 3 reasons: to protect from corrosion, assure good paint adhesion, and in applications where electrical conductivity is needed. The coating is formed through a reaction between the surface and the chemical conversion materials. This produces a super thin coating (a film) on the metal substrate, with a thickness between .00001” to .00003”. Here at KMF, we offer chromate on zinc and aluminum. Please see below for more information on trivalent chromates.

Trivalent Chromate (Cr3) (also called trivalent passivate)

Top coating of zinc has progressed rapidly in the last decade. The early trivalents offered minimal corrosion resistance, due to their thin film build and inability to repair itself while curing as hexavalent could. However, they did give the industry a coating much less toxic. The newer forms of trivalent producing approximately 200-250 micrometers in thickness will render salt spray resistance of 120 plus hours to white corrosion. The heaviest coatings in the 350-450 micrometer range will surpass 250 hour tests. However, they generally do not give the blue-brite appearance of the thin film coatings. The midrange coating thickness meets most of the engineering requirements of today’s industries for salt spray resistance and appearance. One of the great abilities of the new coating is withstanding the elevated temperatures required to drive the hydrogen gas out of an electroplated part, i.e. 400 F (200 C) for 4-8 hours depending on the Rockwell hardness or the part. Chromate can now be applied before baking whereas the old hexavalent chromates could not withstand the temperature in the oven, thus costing additional handling and time, due to having to be applied after baking. We currently offer trivalent chromate in clear/blue-brite, yellow and black.

Specifications include but are not limited to:

Chromate on aluminum specs

MIL-DTL-5541F

AMS 2473 and 2474

ASTM B449

Chrysler PS-1248

See specs listed under zinc plating for chromate on zinc

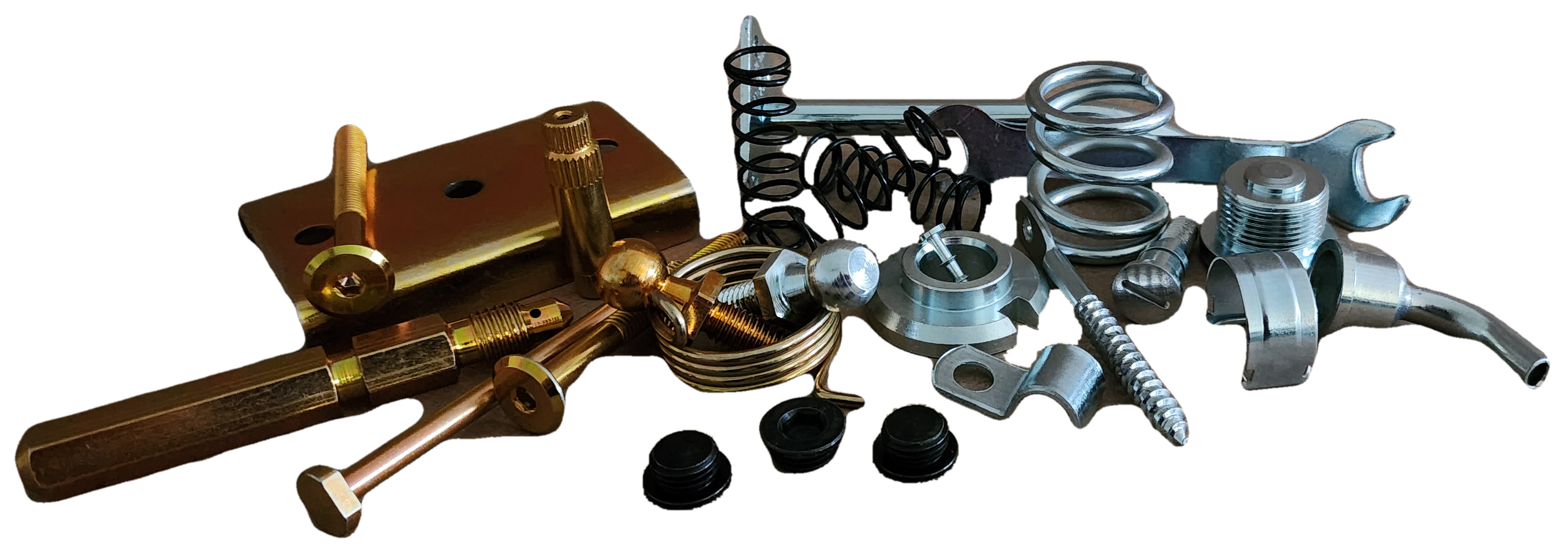

Dip/Spin Paint

There are several reasons that dip/spin has become the go to coating for many industries. First, dip/spin is an economical and effective system for coating high volumes of small parts. Second, it is environmentally friendly. Third, it greatly increases the corrosion resistance. Finally, it has demonstrated an ability to reduce or eliminate the problem of hydrogen embrittlement.

The name of the process depicts exactly what the process is. First, parts are loaded into a wire mesh basket, typically 12-24 inches in diameter. They are then placed in a chamber containing a paint vessel. Next, the chamber is closed and the process is started. The vessel lifts to encapsulate the mesh basket and the basket is submerged to coat the parts. Then the vessel lowers partially so the basket is out of the paint and the basket spins to remove approximately 85% of the excess paint. Finally, the vessel lowers all the way and the painted parts are put on a conveyor belt to be sent through an oven for curing.

This process is most often used over our phosphate coating but can be put over bare metal. It can be done with any kind of water-based paint, including paint specifically approved for the automotive industry. We currently offer yellow, black and blue paints. Our dip/spin process is ROHS, REACH, ELV and WEEE compliant.

Specifications include but are not limited to:

GE F65A1/2 & F69A2

GM6174M & 4350M & 4435M

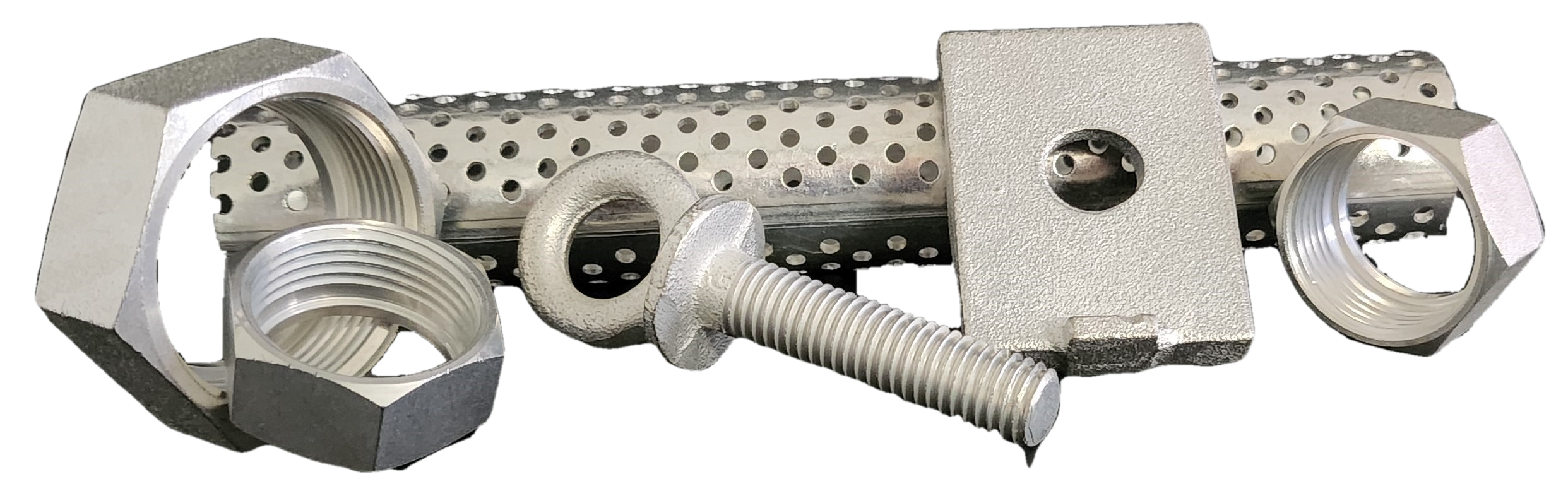

Passivation

The main purpose of passivation is to remove free iron and other foreign material from the surface of stainless steel parts that are left on the surface during the fabrication process. This helps restore the natural corrosion resistance of the stainless steel by allowing it to set up its own chromium-rich, corrosion resistant barrier. Here at KMF, we passivate using nitric acid and provide both rack and barrel passivation. ROHS, ELV, WEE compliant.

Specifications include but are not limited to:

ASTM A380 & A967

Chrysler PS-1604

QQ-P-35

Phosphate

Zinc phosphate is a coating used on metal parts for corrosion resistance, lubricity, or as a foundation for subsequent coatings or paint. A dilute solution of phosphoric acid and phosphate salts is applied via immersion and chemically reacts with the surface of the part to form a layer of insoluble, crystalline phosphates. Typically, there are 3 weights, or thicknesses of this layer, depending on manufacturers’ specifications. The lightest or thinnest coat is no more than 200 mg/sq.ft. Many gear manufacturers request this due to the natural lubricity of the zinc phosphate aiding in a smooth run in in their gear cases. The middle weight range is anywhere from 1000-2500 mg/sq.ft. This coating is the weight most often required. The heaviest coat, consisting of 5000 or more mg/sq.ft, is primarily used in industries where maximum protection from abrasion is concerned.

Phosphating of steel substrates has become the go to coating in the recent decade due to its ability to be a less toxic coating for priming metal for paint, oils and other topcoats. The process lends itself well to a mass produced barrel and static rack operation. We have the standard gray color as well as black. We offer many kinds of topcoats, including clear seal, oil, and wax. Our zinc phosphate process is ROHS, REACH, and ELV compliant.

Tin

Tin metal has been a viable component in the metal finishing industry for a remarkable number of years. It is used to protect both ferrous and nonferrous surfaces. Its properties are useful in the food processing industry and the electronics industry. Tin is non-toxic, ductile, corrosion resistant, and solderable. It is widely known that tin was a major contributor to the canning industry, allowing us to move from earthen materials, such as clay and glass, to ferrous metals for food preservation. Tin also has the ability to conduct electricity without the inherent corrosive properties of copper. A multitude of copper electrical connectors are tin plated today, to avoid the additional expense of gold plating. Another property of tin is its low temperature melting point of 450° F, allowing it to be readily solderable.

We are very proud of our tin process and our growth in the industry in the last 10 years. Our tin process is REACH, ROHS, and ELV compliant. Our tin also meets the international Conflict Mineral mandate.

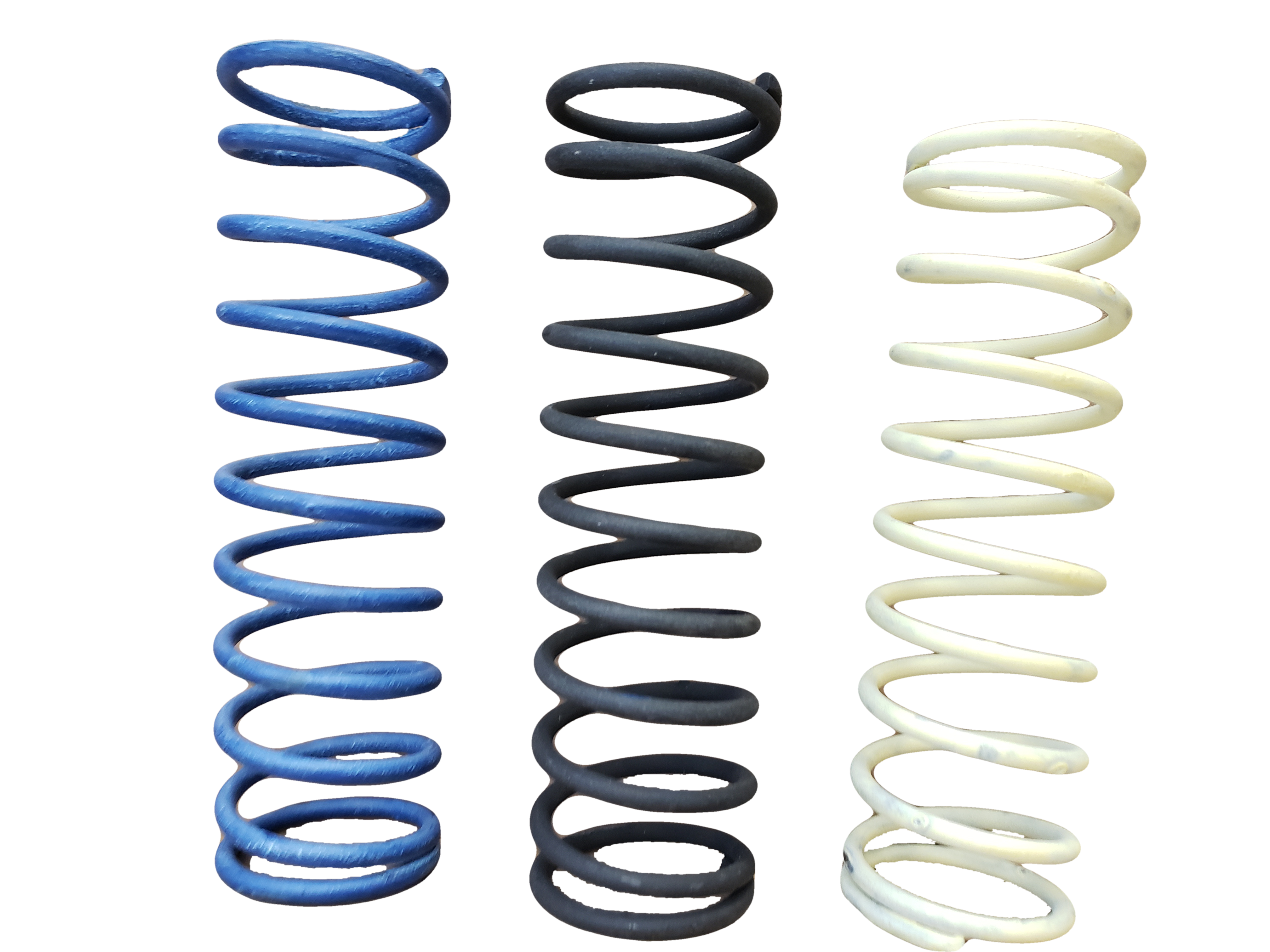

Zinc

Zinc is a metallic chemical element commonly found in the earth’s crust. In its natural state, zinc has a shiny, bluish-white appearance, although most commercial-grade zinc has a dull finish. When electroplated onto a part, the zinc works as a sacrificial layer intended to corrode at a given rate to protect the part.

The zinc is applied as an expendable electrode in a cyanide, alkaline non-cyanide, or acid chloride salt solution. Cyanide baths are the most efficient but can potentially create pollution and are hazardous. Here at KMF, we use an acid chloride solution, which offers a luster finish unequaled in the alkaline solution. Many of the parts we plate end up with a bright finish on par with nickel and chrome but at a much lower price.

After alkaline cleaning, pickling to remove surface oxides, and rinsing, the parts are loaded into a barrel and immersed in the plating solution. Barrel plating renders an even metallic coating over the entire surface of the part versus rack plating, which has electrical current density issues, causing an uneven coating. Zinc is electroplated onto the part at a thickness anywhere from .0001” to .001”, depending upon the specification and/or the application of the part; the thicker the plate, the longer the corrosion resistance.

Post-plating treatments may be used to passivate or chromate the zinc surface as well as impart various translucent colors or to further enhance the corrosion resistance. We offer Trivalent passivate (Cr3+) in clear, yellow and black. (For more information on chromates, see our chromates page.) We also offer several types of topcoats, including polymer sealer, oils, waxes, and torque release compounds.

Contact Us

Address

2019 Glendenning

Kalamazoo, MI 49001

Phone

(269) 382-1611

info@kmfi.com

Hours

Office:

Mon - Thu, 6:00 am - 4:00 pm

Shipping & Receiving:

Mon-Thu 6:00 am - 4:00 pm